- The foundation phase of any construction project will typically follow on from some element of reduced level operation.

- The site engineer must review the drawings and carry out checks to identify any issues or outstanding information as required.

- Drawings need to be checked and reviewed. Apart from identifying errors and omissions by the originator you have to ensure you have sufficient information before setting out the work.

- Always read the notes on the drawings, this can have valuable information, which isn’t shown on the drawings and avoid issuing RFI’s for information already provided.

- Issue requests for information (RFI’s) are requested in the event of errors, omissions and additional information required to carry out the work.

- You may have suggestions to aid in the construction or value engineering options to discuss with the design team.

- You will need to carry out checks on the drawing, comparing dimensions between the architect, engineer and structural steelwork contractor.

- It is not uncommon to discover errors or inconsistencies between different originators drawings.

- Review the drawings to determine the excavation levels; it may be advisable to mark up a drawing with the varying dig levels, if the pad and pile caps have varying depths, don’t forget to allow for blinding if specified on the drawings.

- Formations may be given as figures below finished floor levels and you may be required to look at another drawing to determine the information you require.

- Review the sections to determine and locate different build ups of floor or slab construction. Calculate the setting Information.

- Make sure you have queried any erroneous information and have sufficient information to set out the work. The drawings may only give the corners of the building or refer to the centre of the foundation requiring you to calculate the coordinates of the points as required.

- This will involve reviewing the drawings and calculating the volume of each pad or pile cap size and strip footing/ground beam.

- Check that the drawings you are working to are current and that there have been no revisions in the drawings, marking all superseded drawings with S/S or alternatively superseded if you have a stamp.

- Never dispose of superseded drawings; they are useful for historical records and in the event of mistakes onsite tracing the origin.

- Always thoroughly review the latest revision drawings, compared with the previous revision. Do not rely on the engineer or architect to cloud revised items.

- Finally ensure that the operatives are working to the latest revision drawings if you have issued them copies or extracts.

- Record keeping maintaining records is an important role of the site engineers both for quality assurance purposes and to ensure that your employer can get paid for the works completed.

- Failure to maintain site records can result in your employer not being paid the full sums owed to them.

- You should retain a copy of all drawings and information you issue to the workforce, contractors and client/employer.

- Firstly in the event they lose their copy and need a replacement and secondly to determine responsibility in the event of an error or omission.

HOLDING DOWN BOLTS CONSTRUCTION OF TEMPLATE

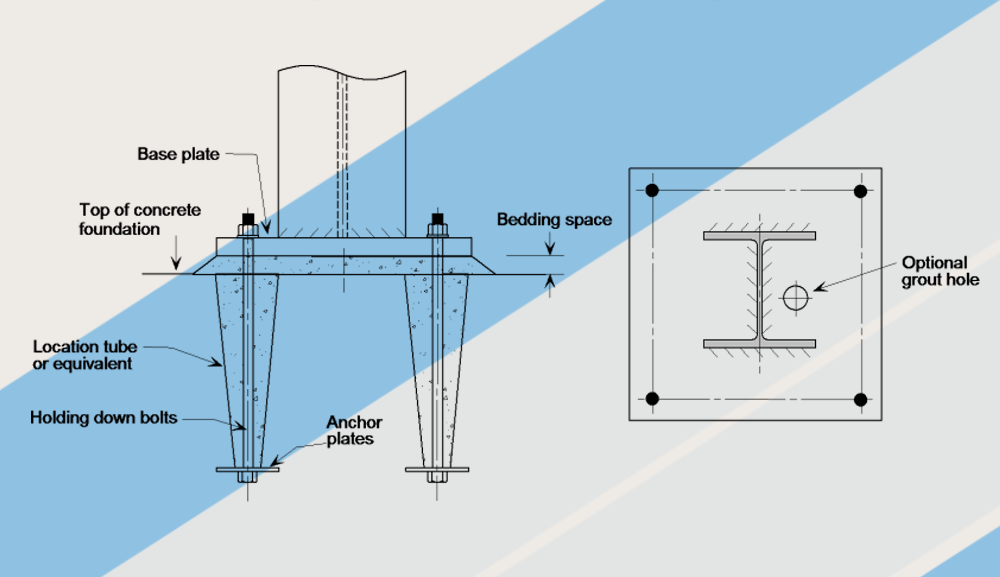

- Typically the structural steelwork contractor will issue a general arrangement or GA and a holding-down bolt detail drawing prior to the foundations starting. These two drawings will need to be read in conjunction with each other, the GA will show the location and type of Holding Down configuration whilst the detail drawing will show the different types, number of each type, dimensions from grid, embedment and projection above top of concrete.

- As the site engineer you most likely will be responsible for managing the joiner’s onsite, who will be responsible for manufacturing the plywood templates for the base plates.

- Ensuring that the right quantity of each type and variety of types is manufactured in preparation for following days requirements.

- The holding down bolt, nut and washer plate will be specified and most likely be supplied by the steelwork contractor.

- The groundworks contractor will be responsible for supplying the ply template, denso tape and wax paper cone. The cones are to allow the bolts to have a construction tolerance, rotating within the circumference of the cone, whilst the denso tape ensures the head of the bolt has the freedom of movement to allow the rotation within the cone.

- Ply templates may be reused however it is advisable to not remove, as this will open up the wax cones to debris which may restrict movement of the bolts.

Please Get In Touch Or Send Your Layout Drawings To “sales@boltbox.co.uk”

We Will Price And Advise On Our Current Lead Times.

FOR A QUOTE, TO ORDER OR FOR ADVICE, call 07929142325 or email sales@boltbox.co.uk

BOLTBOX offer services ACROSS THE UK. Wales, Scotland, Ireland, London, Birmingham, Edinburgh, Cardiff, Manchester, Liverpool, Hull, Lancashire, Burnley, Blackburn, Rossendale, Todmorden, Preston and all other locations in the UK. Call for details or email sales@boltbox.co.uk